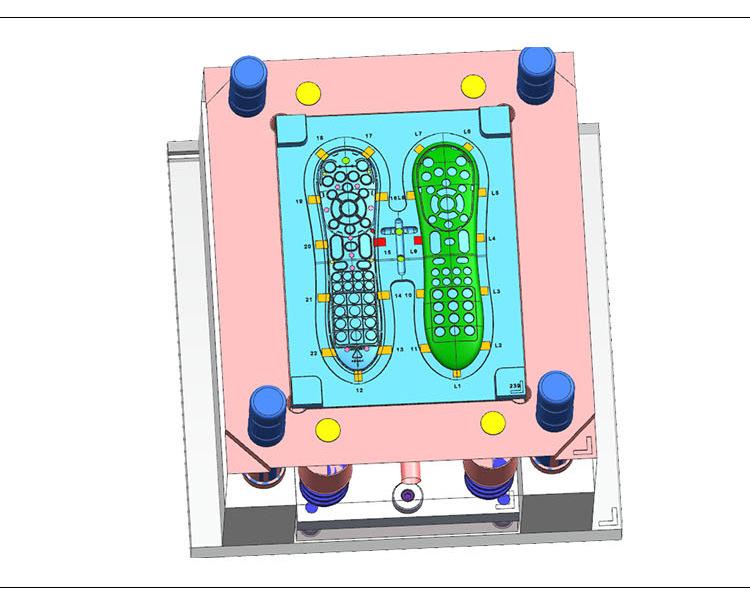

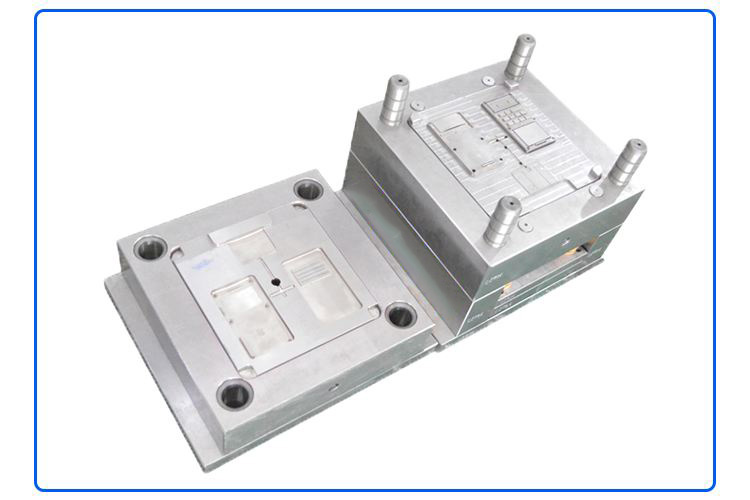

The remote control mould

Injection molding of remote control usually involves injecting molten plastic into the mold cavity and forming the required parts after cooling. When the ejection temperature is reached, the mold is opened and the parts are removed. Because the remote control has small size, side convex and concave structural characteristics, the existing injection mold should avoid because of unreasonable design, so that the finished product cavitation, weld marks, even warping deformation and other defects, resulting in low production efficiency and low product pass rate problems.