Detailed explanation of waterproofing design technology in product development

Detailed explanation of waterproofing design technology in product development

For a product, the customer does not require waterproof structure, but the user often uses it in the position with high density of water molecules. For example: bathroom, etc. So out of the responsibility for customer service, but also reflects the responsibility for precision mold products, but also for the health factors of consumers, precision mold product development team will usually put forward improvement suggestions to customers: improve the structure of the product, in order to achieve waterproof effect.

So what is the IP protection level?

It is drafted by IEC, according to the characteristics of dustproof and moisture resistance of electrical appliances to be classified, composed of two numbers, 1 number represents dustproof, prevent the invasion of external objects, 2 number represents moisture resistance, waterproof invasion of airtight degree. The higher the number, the higher the protection level.

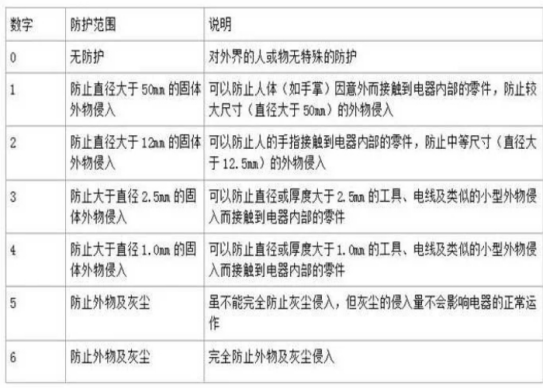

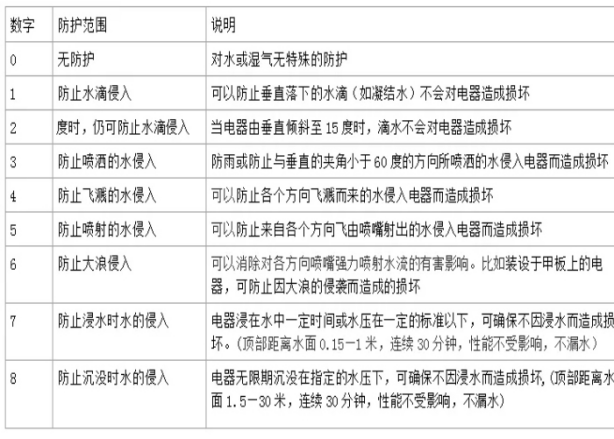

The following table can be seen:

A designation of the level of protection referred to by a characteristic number (number)

The two marks indicate the degree of protection referred to by the characteristic number (number)

Protection grade IP67, for example, to the IP letters, number 6 as a tag number, representing completely prevent dust intrusion, have dust intrusion will affect the normal work of the machine, 7 as the second tag number, on behalf of the machine can be immersed in the water a certain time or water pressure under certain standards, to ensure no damage due to flooding.

The universal waterproof structure used by the product development team is:

1. Compressible soft rubber

Soft rubber waterproof ring: rubber, silica gel, TPU,TPE,PVC, etc., different materials, hardness grade is also different, usually used in the body shell waterproof. You can use a separate soft rubber ring, you can also design plastic mold, soft rubber on hard rubber, vertical injection molding is a process to solve the problem of beer, and then fastening through the lock screw. Our company's beauty instrument custom plastic mold products at this stage mostly adopt this way.

2, plastic ultrasonic connection class

3, waterproof glue

The choice of waterproof structure according to the product definition, precision mould product appearance to choose, if high waterproof grade, waterproof success, need to constantly test, sometimes after the products assembled, just start testing, may be passed, but after high and low temperature test, drop test, after water pressure test, etc, could not waterproof, So it takes constant adjustment to get better results. High waterproof machine generally uses components to adjust the air pressure, if not, it is necessary to design the air outlet of the air permeability film, to prevent the product cracking problem caused by different air pressure.